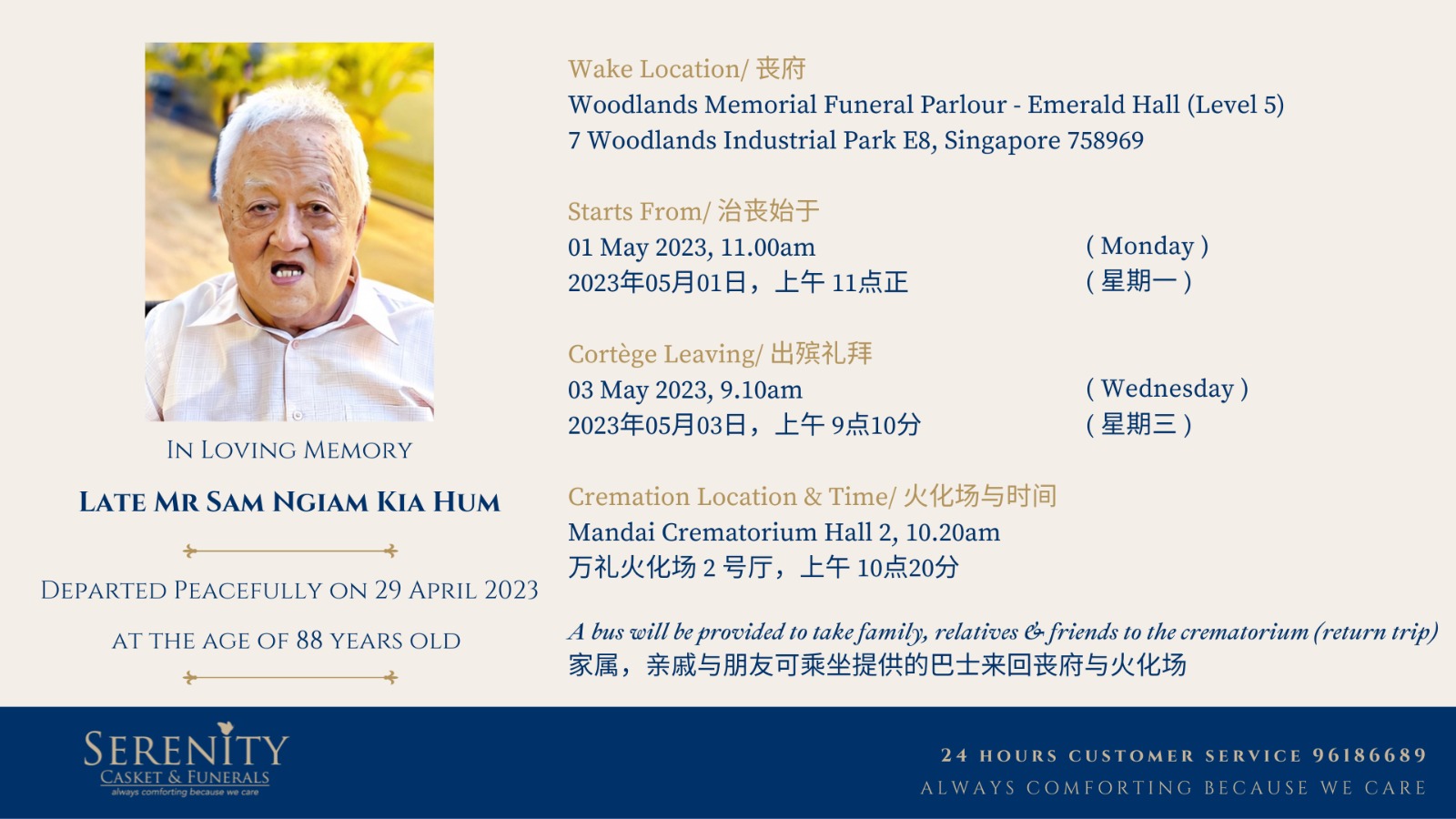

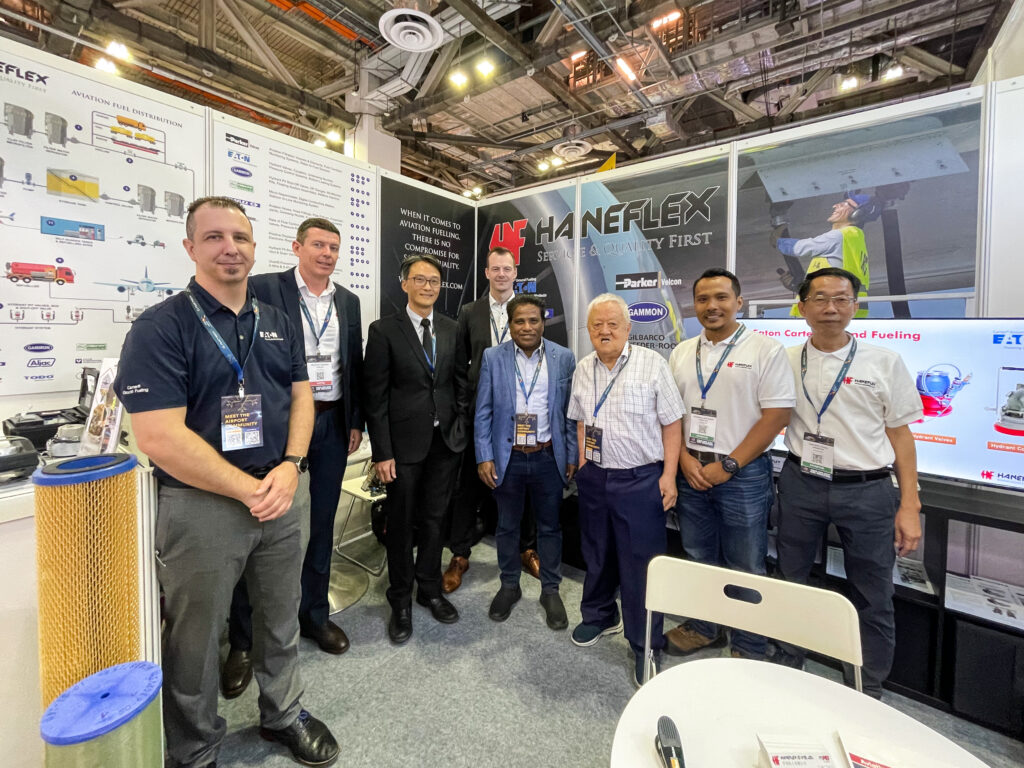

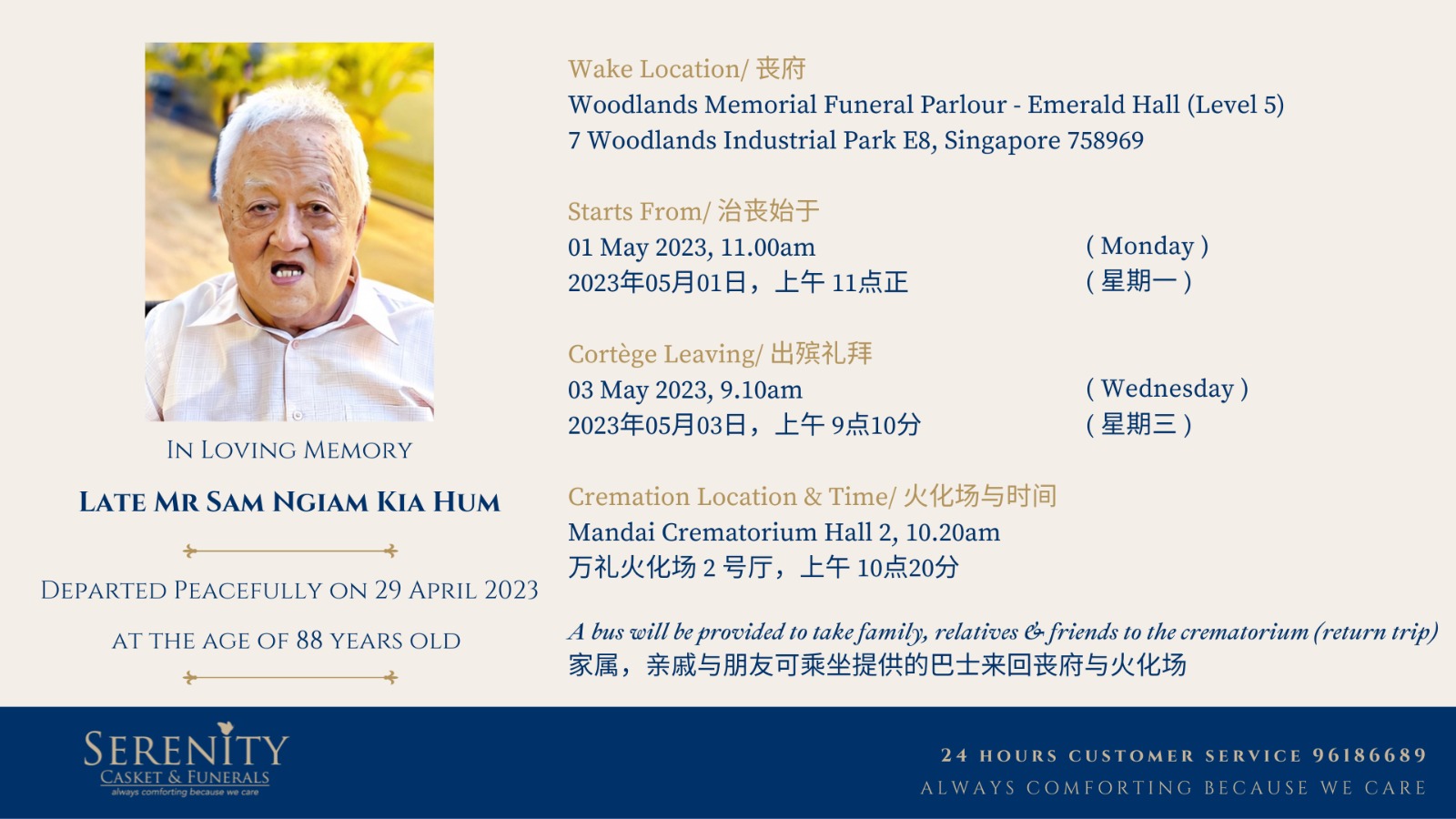

It is with great sadness and regret for us to announce the passing of our beloved company founder, Sam Ngiam.

Sam started Haneflex more than 40 years ago back in 1980. The company started as a small workshop providing maintenance services for petrol station equipment and have since grown to be one of the most established distributor of aviation fueling components in Asia today.

He was greatly respected by his peers in the industry and he continued to come into the office daily up to the very end.

Haneflex will continue to be managed by his son, David Ngiam.

Sam …

Please see the attached Clarifier from Parker Velcon. Here are some highlights:

Please see the attached Clarifier from Parker Velcon. Here are some highlights: