Our office will be closed from 24-27 February 2019, to celebrate the Lunar New Year.

We would like to take the opportunity to with all friends and associates good health and prosperity in the Year of the Rat!

…

…

Our office will be closed from 24-27 February 2019, to celebrate the Lunar New Year.

We would like to take the opportunity to with all friends and associates good health and prosperity in the Year of the Rat!

…

…

The Veeder-Root team is announcing the end of production of new systems and the sale of our 8470, TLS-350, 8482 TLS-350, 8485 TLS-300, 8560 TLS-2, and 8546 TLS-50 Series ATG systems. Each system has reached the point in its life cycle whereby manufacturing the product is not feasible due to obsolete components, the increased cost of older technologies & production techniques plus a higher cost of maintaining the product.

For more information, please see the following :

Product Transition Information

We recommend customers transition to the Veeder-Root TLS-4xx Series console for their tank monitoring needs. The TLS-4XX

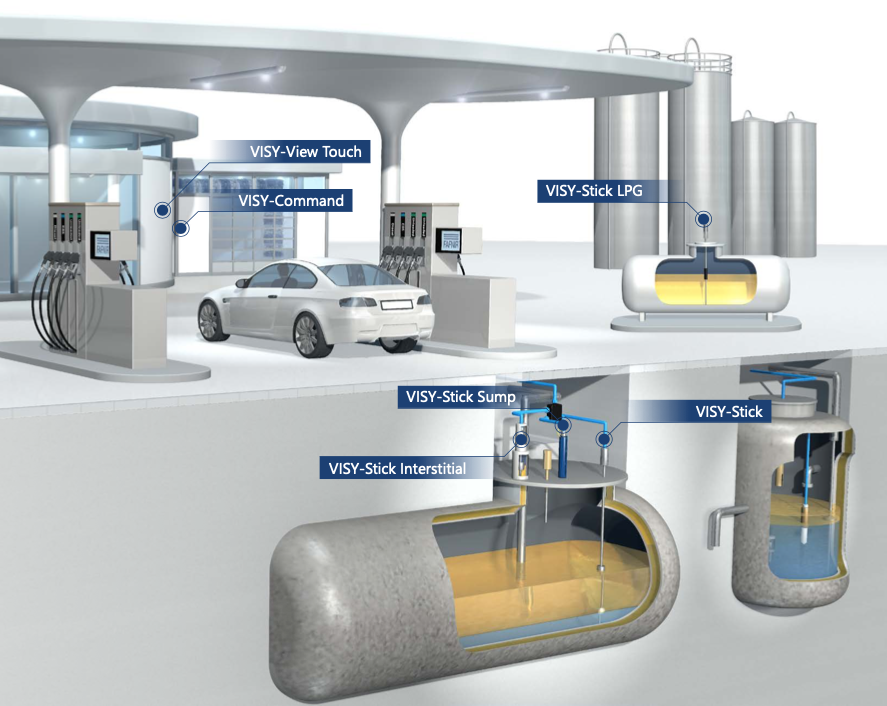

Haneflex is pleased to announce that we are now the distributors of FAFNIR for Commercial Fuel Dispensing and Process Automation. FAFNIR is also now part of the Gilbarco Veeder-Root family, so their systems are complementary to the GVR eco-system

FAFNIR are specialists in the development and manufacturing of sensors and systems for monitoring and measuring fill levels. They provide the latest technology in fuel management systems and solutions which allow our customers from the oil, chemical and pharmaceutical industries to fully put their trust in our products.

For full details on their product range, visit www.fafnir.com

…

…

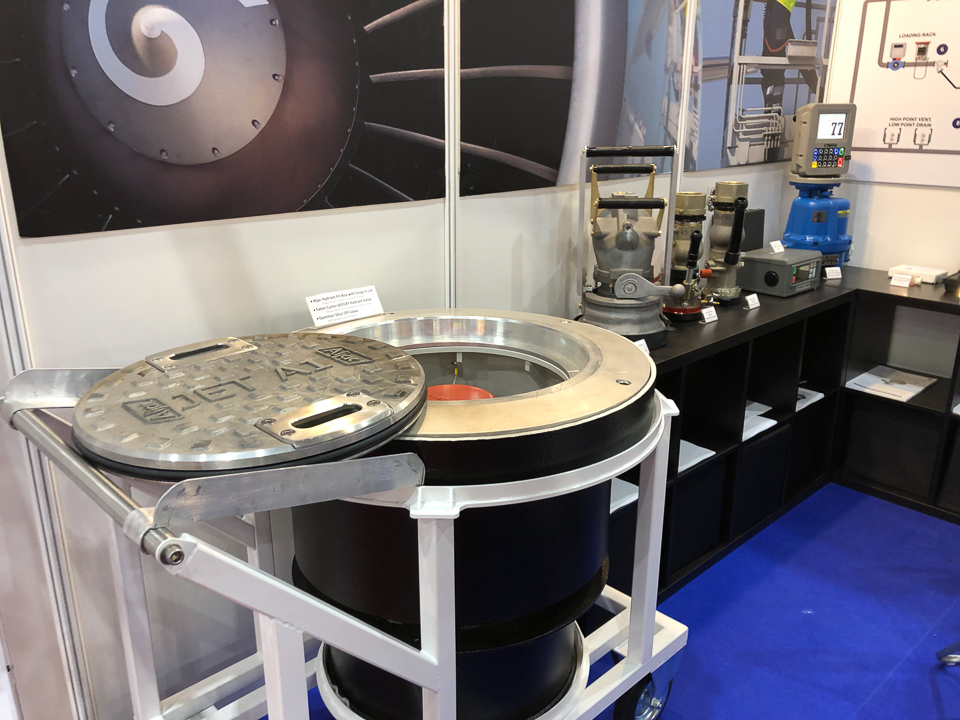

Eaton’s Carter® product line of ground refueling equipment includes the 4th Edition of our Digital Pressure Control System, which employs a proprietary method of controlling and monitoring fuel pressure into the aircraft. The combination of Hydro-mechanical valves and a microprocessor eliminates the need for air-reference pressure, servo controls or venturis to control pressure. Fuel cannot cross contaminate the air system such as occurs in air operated systems.

For more information, download the catalog below:

Please see the below announcement from Parker Velcon regarding the availability of Monitors in light of the eventual withdrawal of the EI 1583 specification.

Please see the following update below from Parker Velcon regarding the new Parker Velcon CDFX that is designed to replace the 2″ monitors. Note that the Parker Velcon CDFX™ is the ONLY ‘true drop-in’ solution available that can remove both dirt and water without the need for additional equipment and/or electronic sensors (as currently with EI 1581 and EI 1583).

[CLARIFIER] Parker Velcon CDFX™_ The Facts About the New EI 1588 Water Barrier Technology…

Parker Velcon CDF-X™ elements are currently going through robustness testing at two major airports in the U.S. This is part of the testing program to determine if the elements will be safe for into-plane field evaluation. Unlike previous new products that have followed EI filtration specifications, the CDF-X is the first to require robustness testing. In our lab, we are able to produce results that indicates extended life expectancy surpassing the current EI1583 specification. Stage II of the robustness test requires a throughput of 650,000 gallons of fuel per element. This type of testing cannot be completed in a laboratory …

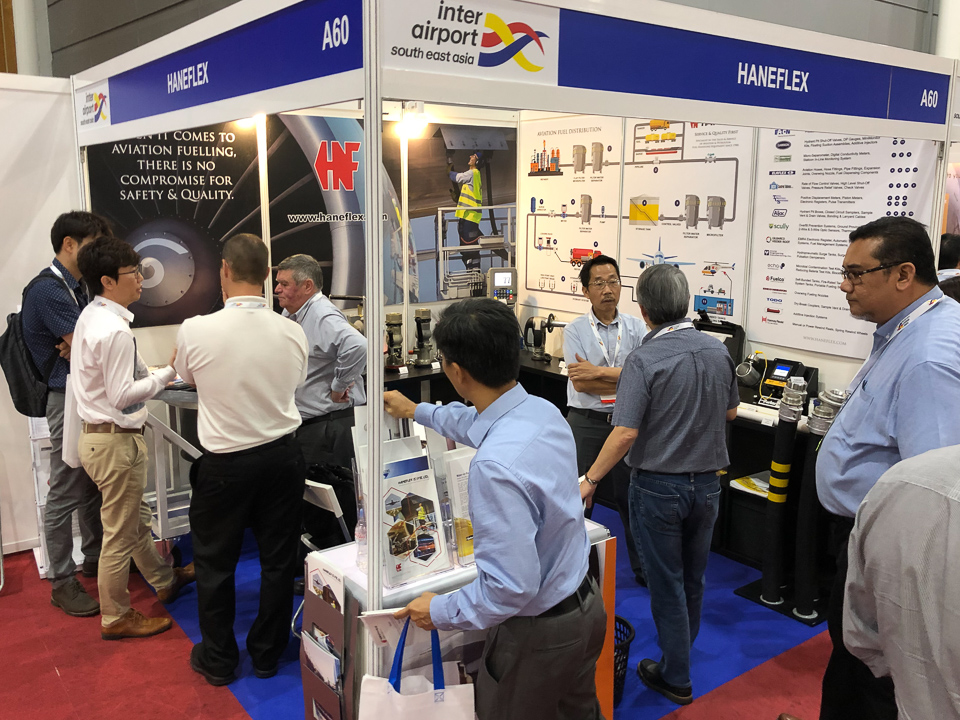

Haneflex had the pleasure of participating at InterAirport SE Asia 2019 held at the Singapore Expo in February. Our stand was visited by many of our customers around the world and we had the privilege of having our principals join us as well and engage with end-users.

We also had a chance to showcase the latest products and technologies which had shown alot of keen interest! It was a very successful show and we look forward to being a participant again in 2021!

…

…